Selector switches in the machine building industry: functions, benefits and application areas

Compact and safe operating concepts for the machine control

With growing automatisation, the requirements for operating interfaces on machines and plants have increased. More functions, more operating modes and complex processes call for clear, space-saving and fault-free controls.

In this article, you will learn more about the technical operating principle of selector switches, what is the difference between maintained and momentary and where the control units are frequently used.

Operating principle of selector switches

Selector switches – mechanically fixed positions

A selector switch is an electromechanical control unit with which different operating modes or functions can be distinctively selected. The selected position is maintaned, that means: It stays fixed until it is changed consciously and thus offers constantly visible operating statuses which is reducing faulty operations especially in industrial manufacturing.

Construction:

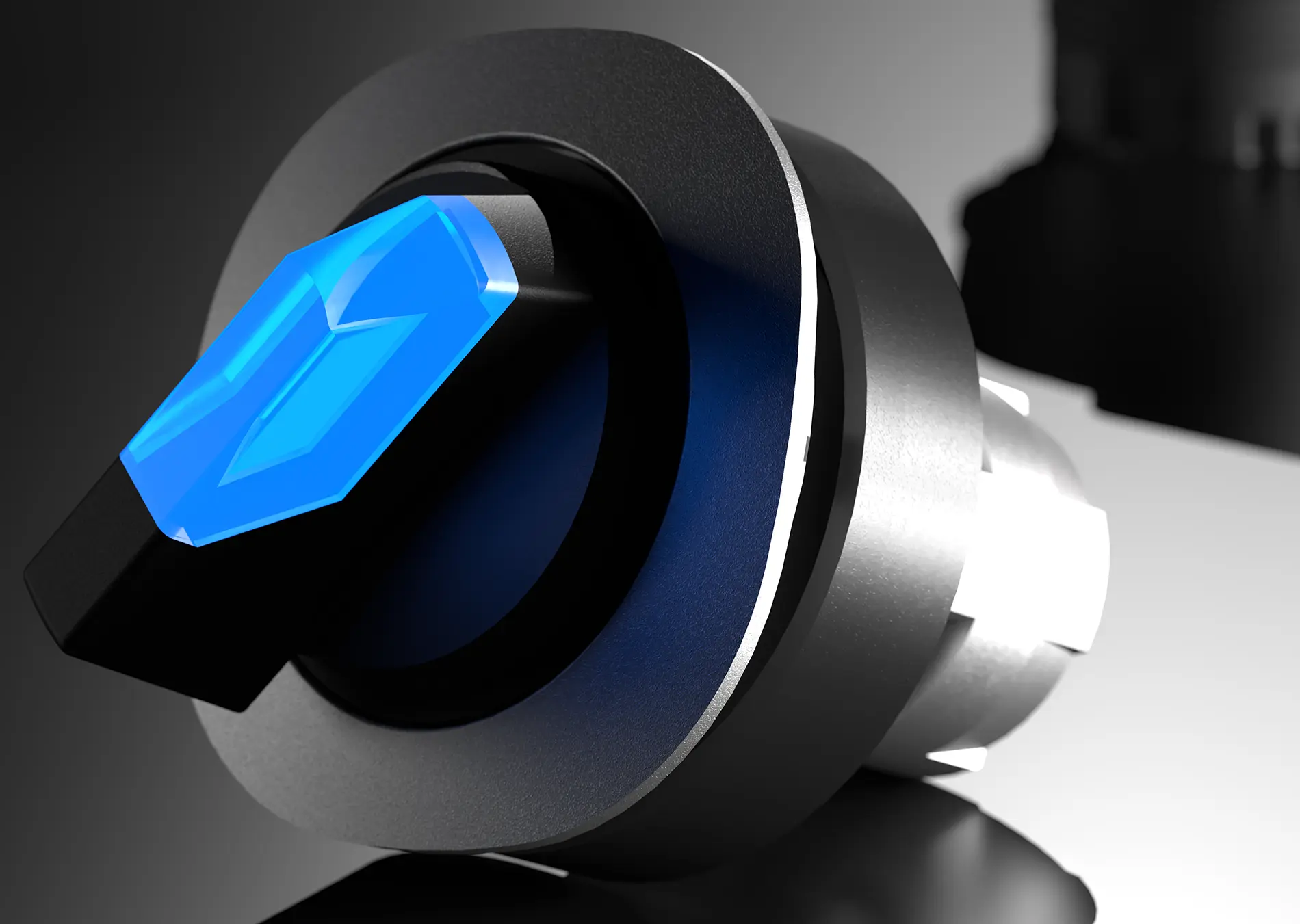

Actuator: Selector knob, lever or key, switching unit with defined maintained positions, contact modules to activate the circuitsSelector switches – momentary and flexible

WWhen a selector switch is maintaned, it means: The switching position is only active while it is being held in this position. It is not fixed and returns automatically to the original position (temporary impulse).

They are ideal for start-stop functions, reset commands or safety-relevant applications for which only a temporary impulse is necessary.

Maintained or momentary – choosing the right function

The choice for maintaned or momentary depends on the application. But it’s not „either – or“ as a combination of both is also possible. With this, constant operating modes and temporary commands can be realised flexibly.

Varieties of selector switches

Rotary selector switches are the most commonly used type and are suitable for fixed operating modes like "on", "off" or "auto".

Multiposition selector switches offer three, four or more maintaned positions and combine multiple functions within one element which saves space and reduces the wiring effort.

3-position selector switches are momentary, return to their original position after releasing and are suitable for applications like enabling switches or temporary operating commands. They are especially useful when short impulses are needed for safety-relevant processes. Key switches increase safety as only authorised personell with a key can change an operating mode, for example during maintenance or for safety-critical functions.

Optionally, all types can be equipped with illumination, combined key operation or various contact types to improve the operating logic and clarity.

Safety and efficient machine control

It is a basic requirement for the machine building industry that machines can be operated safely and efficiently. That the various operating modes can be selected clearly is an important aspect for this to prevent faulty operations. Thus, selector switches contribute to safety and process optimisation:

- Clear operating statuses: Mechanically maintaned selector switches always indicate clearly which mode is active, e.g. manual operation, automatic or maintenance mode.

- Safety functions: A momentary selector switch provides precise control impulses for emergency-stop, reset or enabling switches.

- Error reduction: Intuitive operating logic, haptic feedback and illuminated switches or buttons contribute to reduce operating errors.

- Access restriction: Key switches allow only authorised personnel to change critical operating modes.

- Robust design: Mechanically stable construction and a degree of protection of up to IP67 ensure the operating safety also under demanding industrial conditions.

Typical application areas for the machine control

The devices are used in many industrial areas.

Typical examples:

- CCNC machines: Changing between manual operation, automatic, reference movement or maintenance

- Conveyor plants: Selection of different conveyor lines or operating modes

- Packing machines: Selection between production, cleaning or stop

- Crane control: Selection of lift, drive or maintenance mode

- Processing plants: Control of pumps, valves or mixing cycles

- Building automation: Changing between automatic, manual or service

Thanks to their intuitive operability and high robustness, selector switches are an integral part of modern operating concepts.

Selector switch or touch panel?

Today, touch panels are also often used on machines. But they are not always the first choice for a machine control because the touch panels, too, don’t just have benefits, but also disadvantages:

- Touch panels are flexible and ideal for visualisation and displaying of processes, however, are sensitive to malfunction.

- Selector switches convince with their robustness, low maintenance and intuitive operation. The haptic feedback ensures the operator that an operating command has been registered.

In practice, in many cases a combination has proven successful to use the benefits of both technologies: Touch panel for visualisation, selector switch for critical and frequently used operating modes.

Schlegel products: modular, robust, flexible

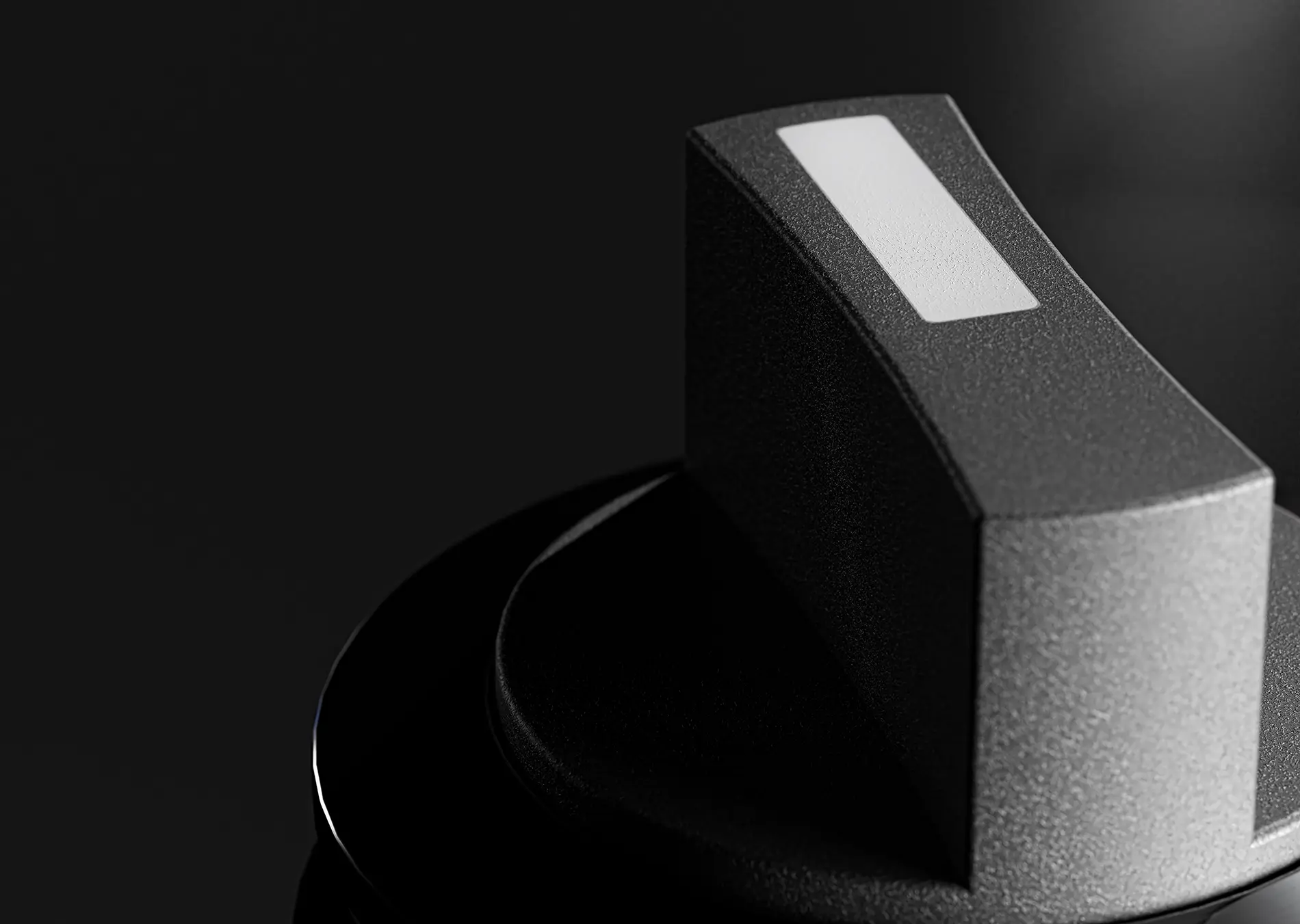

SCHLEGEL offers a great variety of modularly combinable selector switches that are ideal for the industrial machine control:

- 2 positions or 3 positions; momentary, maintaned or a combination of both

- NC, NO and other combinations

- Degree of protection of up to IP67: suitable for demanding operating conditions

- Various front bezel colours and panel cut-outs: 16.2 mm, 22.3 mm, 30.5 mm

- Connection types: Choice between different variants – screw connection, Faston terminals, PCB-mount terminals, M12, AS-Interface or spring-clamp connection

- Shape – there are also various possibilities for this: round, rounded or square shape

- Optional equipment: different contacts and illumination

Thanks to this flexibility, Schlegel selector switches can be adapted exactly to the requirements of the application and offer highest safety, operating comfort and durability.

Conclusion

Selector switches offer a space-saving, safe and robust operating interface for the machine building industry. They reduce the wiring effort, improve clarity and provide an ergonomically reliable operating experience.

The modular, robust and flexible solutions from SCHLEGEL are perfect for machine and plant engineering as well as automation technology and are in accordance with the common standards.

Discover Schlegel switches now or request an individual consulting.