Self-monitoring emergency-stop devices: Safety without compromises

Where traditional emergency-stop systems reach their limits

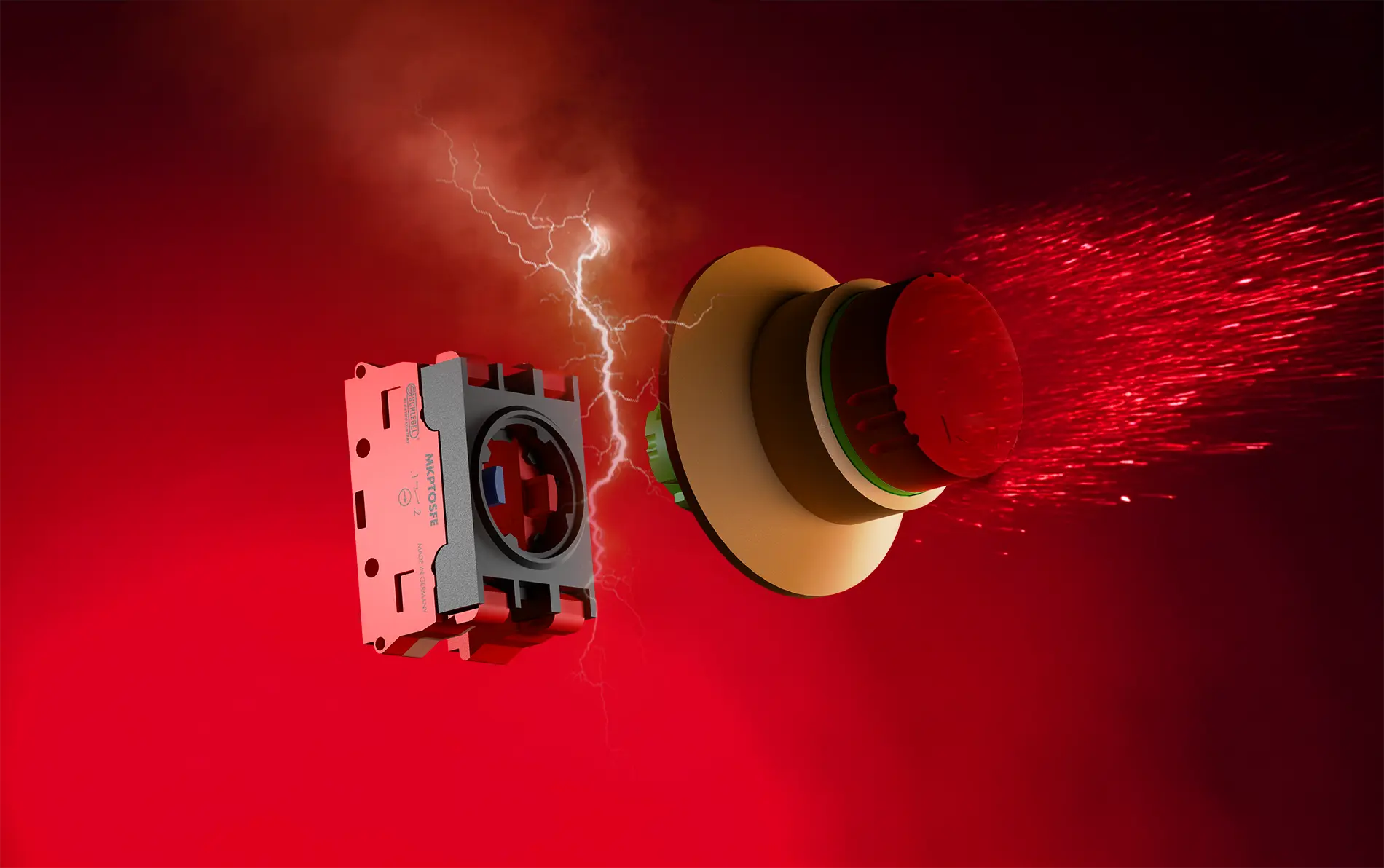

In the industrial field, a split second often decides about safety or accident. An emergency-stop stops machines by pushing the so-called mushroom head – but what if the switch is defect or the contact block is not properly connected to the emergency-stop? If this error remains undetected, the consequences can be grave: An increased risk of accidents and unforeseen production stops.

Self-monitoring emergency-stop contact blocks are the solution for this safety gap that may occur for example due to mechanical damage or neglectful assembly. To prevent any accident due to negligence, they ensure that in such a situation the emergency signal is activated and the plant is switched off immediately. It can only be restarted after successful trouble-shouting.

What is a self-monitoring emergency-stop?

A self-monitoring emergency-stop is a safety-oriented system that not only stops a machine or plant in case of emergency, but also continuously verifies its own status.

If the connection between emergency-stop and contact block is correct, the switch is functional – and the plant is running. In case this connection is interrupted, the machine or plant will be automatically stopped and set into a safe state.

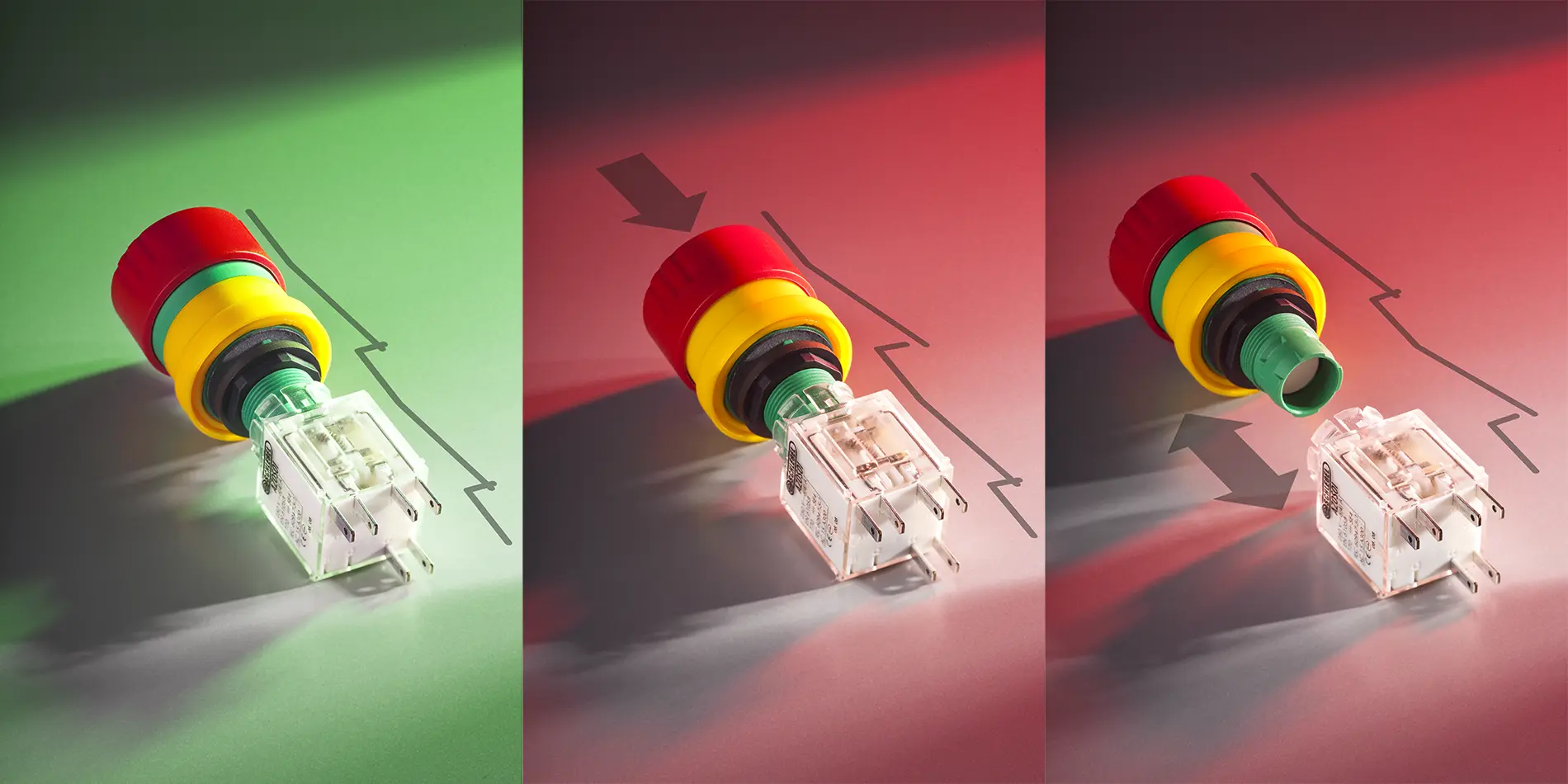

This is how the self-monitoring works

To ensure that the self-monitoring function works reliably, the contact block is equipped with an integrated NO contact. It monitors the connection between emergency-stop and contact block. As soon as this connection is interrupted – e.g. due to a defect or negligent assembly – the additional NO contact is triggered. The safety function will be activated and the machine will automatically change into a safe state.

For this case, a closed monitoring contact displays that the connection is faulty. Only when this failure is being solved and the connection is once more correct, the machine can be started again. This ensures that the plant can only be operated in a completely safe state.

The most important advantages at a glance

A self-monitoring emergency-stop device offers the following benefits:

- Safety: An error detection in real time prevents undetected failures.

- Reliability: The safety function is also given in case of internal defects.

- Compliance with standards: It fulfils international safety standards.

- Productivity: Less shutdowns thanks to predictive failure diagnosis.

Which standards have to be fulfilled?

For safety systems to be effective, they have to comply with the standards and specifications:

- EN ISO 13850: Defines the requirements for construction, usability and function of emergency-stop systems.

- IEC EN 609467-5-5: Determines the safety-related requirements for emergency-stops and emergency-stop devices that are operated electrically.

- Obligation for maintenance: Regular tests, documentation and personnel training are indispensable.

Practical orientation: Solutions from SCHLEGEL

SCHLEGEL offers a great variety of contact blocks with integrated self-monitoring that can be combined flexibly with the extensive emergency-stop porfolio. Thanks to that, various requirements for safety, functionality and design can be fulfilled.

The following contact blocks with self-monitoring function are being offered by SCHLEGEL:

- MTOSFE: self-monitoring emergency contact block that requires one place in the module holder

- AZSOSO: contact block with integrated failure switch-off for emergency-stops

- AZOSOI_AU: self-monitoring contact block for emergency-stops

- AZOSOI: self-monitoring contact block for emergency-stops

- AZSOSO_AU: contact block with integrated failure switch-off for emergency-stops

- MKPTOSFE: self-monitoring contact block from the MK series with Push-In connection

- MKTOSFE: self-monitoring contact block from the MK series with screw connection

- DTOSDE: self-monitoring emergency contact block that requires one place in the module holder

- DMTOSFA: self-monitoring emergency contact block

Special features of emergency-stop devices from SCHLEGEL

- Robust design for demanding industrial environments

- Lockable mushroom heads for additional safety

- Easy integration into existing safety systems

- Extensive portfolio with different shapes, sizes and mounting holes; illuminated and non-illuminated

Emergency-stops from GEORG SCHLEGEL GmbH & Co. KG are used in a wide variety of industries. The application areas range from machine building to the use in medical technology and the railway industry. They can be found in complex production plants and are also suitable for rough working conditions.

Conclusion: Self-monitoring emergency-stop devices

A self-monitoring emergency-stop is more than just a switch or a red button. It is an important part for a safe production and an important safety aspect for human and machine. Companies that implement this solution not only protect their employees that are working on the machine, but also secure a trouble-free production process.