SW does not only deliver machines, but also complete solutions: Modular processing centres, self-sufficient manufacturing cells, integrated software solutions and integrated automation concepts. For all solutions, the main focus lies on precision, traceability and efficiency. With this, SW consequently pursues the goal to make manufacturing systems scalable and future-proof.

The challenge: A uniform operation with a large variety of variants

For the modular constructed machines of the series A5 (e.g. BA W06, BA7x1 or BA W08), the goal was to realise a uniform operating logic – despite differing configurations and customised requirements. To realise that SW bet on a Profinet or IO-Link compatible operating unit from the company SCHLEGEL. The operating units are used at central access points on the machines to control the workpiece loading or the workpiece loading device.

To realise different functional requirements on the machine, the operating units have been configured accordingly. Not only the technical functionality, but also a uniform and attractive design as well as an easy integration in existign systems was important. SW attached great importance to a robust construction, high quality and an integrated labelling of the pushbuttons. "The SCHLEGEL product range makes it possible to configure individual operating panels with standardised and certified bus interfaces with an attractive design," says René Hermle, director of the hardware development.

Modular, standardised, ready to connect The operating units are based on SCHLEGEL’s modular bus system (MBS) and can be connected directly to the Profinet and IO-Link machine control at SW. The MBS enables a standardised and efficient integration of the operating panel. Thanks to the standardised communication structure, the wiring effort is significantly reduced and at the same time, the risk of wiring errors decreases.

Pre-configured

The operating panels are pre-configured and are delivered with integrated labelling. The operating elements can be parameterised so that for example malfunctions can be identified or the replacement of wear parts can be initiated in time. Furthermore, switching states can be displayed, status indications can be monitored, operating hours can be counted and indicator lights can be controlled – functions, that considerably simplify maintenance and process monitoring.

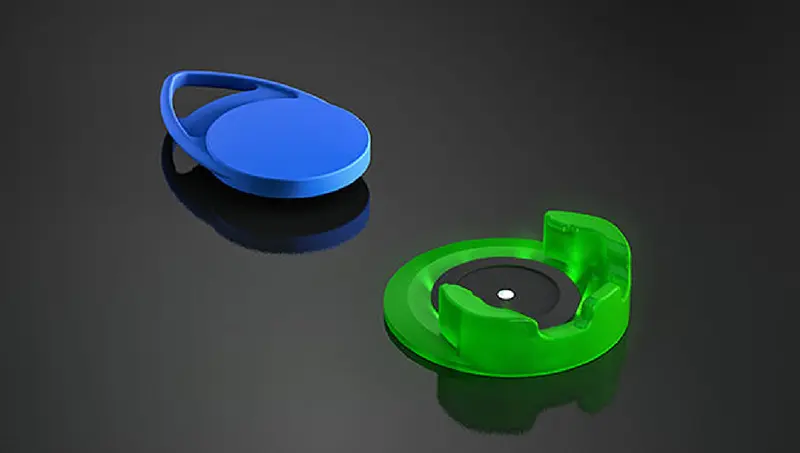

Other features of the MBS are an analogue input with 8 bit A/D conversion as well as the possibility to simply expand the system with an RFID module. The brightness of the indicator lights can also be adjusted flexibly – such as through a dimming function or a night design.

Positive feedback

Positive feedback was given for the high quality of the haptics of the pushbutton during operation as well as the clear assignment of the functions. Regarding maintenance, the teams are profitting from the uniform equipment and a reduced storage need for replacement parts.

The modular design enables series-specific or customised adaptations – without changing the overall construction. This makes the machinery pool standardised, but still adaptable. The implemented operating units have proven themselves in both, the small series and for series production.

Long-standing partnership

SW and SCHLEGEL are connected through a long-standing partnership. For more then 20 years already, both companies are working together, for about ten years this is also true for the area of operating solutions. SW especially values SCHLEGEL’s high flexibility in regards to individual enquiries, the great accessibility and innovative capability in case of new requirements. "Thanks to SCHELGEL’s innovation power – and also to the professional and reliable cooperation since many years – we were able to devise an excellent solution for SW’s operating panels," concludes Hermle. The extensive product portfolio – ranging from pushbuttons to emergency-stops to connection components – offers SW individual solutions and high design and quality at the same time.

With the successful implementation of the Profinet/IO-Link operating unit, the development is far from completed. There is still the goal to make the human-machine interface even more intelligent, networked and easy to maintain.

Conclusion

The integration of the Profinet/IO-Link operating unit in SW’s processing centres show how functional operating solutions can contribute to increase efficiency in the manufacturing. The reduction of technical complexity, the easy scalability and the clear operating comfort make the concept a best practice example for a modern machine operation. Together witch SCHLEGEL, SW managed to establish a flexible solution that fulfills current requirements while leaving room for future developments.