Enabling switch: safety and functionality in industrial applications

An enabling switch is an essential component of many industrial applications to ensure the safety of operators. This essay examines the technical features and benefits of this important safety element.

Key facts

- Enabling switches are essential safety elements in the industrial sector.

- The 3-step logic (on-off-on) offers maximum security.

- A degree of protection of IP65 and robust design enable an application in rough industrial environments.

- They are used for robots, CNC & pressing machines and more.

- A wide variety enables a flexible integration.

- Technical documentation supports a safe installation and use.

What is an enabling switch?

An enabling switch, also named enabling device, is a safety-relevant control unit that is used for industrial machines and plants. It ensures that movements or functions are only being started if the operator actively enables them – an essential element in regards to functional machine safety. Especially in hazardous areas, an enabling switch protects both the operating personnel and the plant with a clear, defined 3-step safety logic:

Off – On – Off.

Remark: The market also offers 2-step models, but the extended logic (3-steps) is most commonly used.

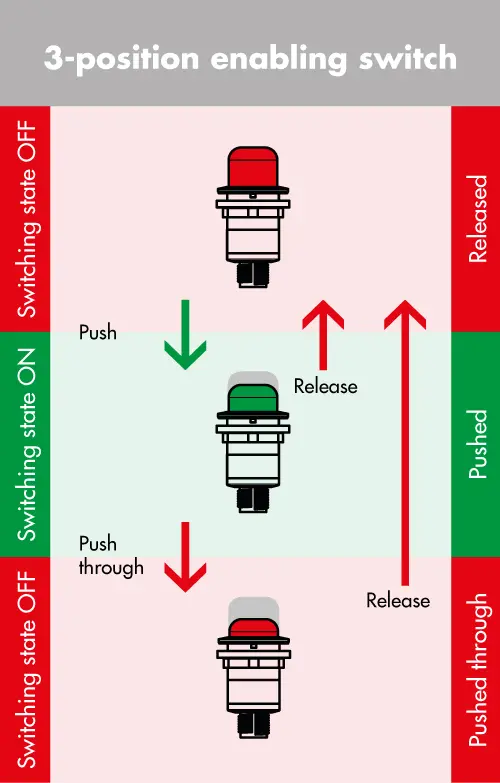

3-step function for maximum safety

The enabling switch's function is based on 3 clearly defined steps:

-

Step 1 – Off (not activated): No signal, machine is off.

-

Step 2 – On (middle position): Enabling activated, machine is ready for operation.

-

Step 3 – Off (completely pushed or released): Immediate stop of the machine.

This logic is especially designed for works like setting up, maintenance or programming processes. Only by deliberately holding the switch in the middle position the machine stays active. When it is unconsciously released – e.g. due to being startled, exhaustion or in a dangerous situation – the power supply will be automatically interrupted (panic function). This maximises safety.

Specifications and installation of the enabling switch

Enabling switches for fixed installation convince by their compact design and simple integration in existing systems. Relevant specifications:

- 3-step switching logic

- Degree of protection IP65 – dust and water-splash proof

- Robust materials for industrial environments

- Exact dimensions (e.g. diameter of rubber cap, mounting depth)

These characteristics make them ideal for the use in safety-critical applications of automation and control technology.

NO and NC contacts can be implemented. SCHLEGEL's enabling switches have 2 NC contacts. Some enabling switches have redundant switching contacts.

Benefits of an enabling switch (3-step)

- Increased safety for personnel in dangerous areas

- Intuitive handling thanks to a clearly perceptible action point

- Immediate switch-off when releasing or pushing through

- Compact design for easy integration

- Reliable technology for permanent load in the industry

Especially products like that of SCHLEGEL set industry standards for reliable safety circuits.

Application areas

Enabling switches are essential for machines where the operator is inside or close to the dangerous area. Typical application areas:

- Industrial robots

- CNC machines

- Pressing machines

- Packaging machines

- Teach-pendants / handheld devices

They comply with the requirements of typical safety standards like EN ISO 12100, EN 60204-1 and the Machinery Directive.

Variants and versions

There are different variants for various industrial requirements:

- Integrated enabling switches in handhelds, e.g. from SCHLEGEL

- Wired or wireless models

- Additional functions like emergency-stops or function keys

- Individually adaptable versions

- The selection depends on the field of use, the risk assessment and the operating concept of the respective machine.

Technical data, support and product information

For correct installation and use detailed assembly instructions, data sheets, product information, dimensional drawings and declarations of conformity are available (also for download). These and other documents ensure:

- Fast implementation

- Secure connection (connection examples)

- Compliance with all relevant safety regulations

A complete scope of documentation is essential for standard-compliant and reliable use throughout the entire life cycle.

Frequently asked questions (FAQ) about the 3-step enabling switch

1. What is an enabling used for?

It enables the safe operation of machines in dangerous areas through conscious manual approval.

2.How does the 3-step logic work?

Only the middle position activates operation. Releasing or pushing through the button initiate an immediate stop.

3. Where is the enabling switch used?

Wherever people are in potentially dangerous machine areas, such as robots, presses, and CNC machines.

4. Are there different models?

Yes – depending on the application, as a device for mounting, as integrated handheld device, wireless, or with additional functions such as an emergency-stop, including two normally open contacts (SCHLEGEL). The enabling switch can also be mounted in an enclosure.

There are also 2-step enabling switches, although the vast majority of models feature the 3-step concept.