Active/inactive emergency-stops: Usage and safety of illuminated emergency-stop devices

Machines and plants have to be equipped with an emergency-stop device in case of dangerous situations. In case of emergency, these devices ensure that machines are quickly brought into a safe state and that risks for users or plants are minimised.

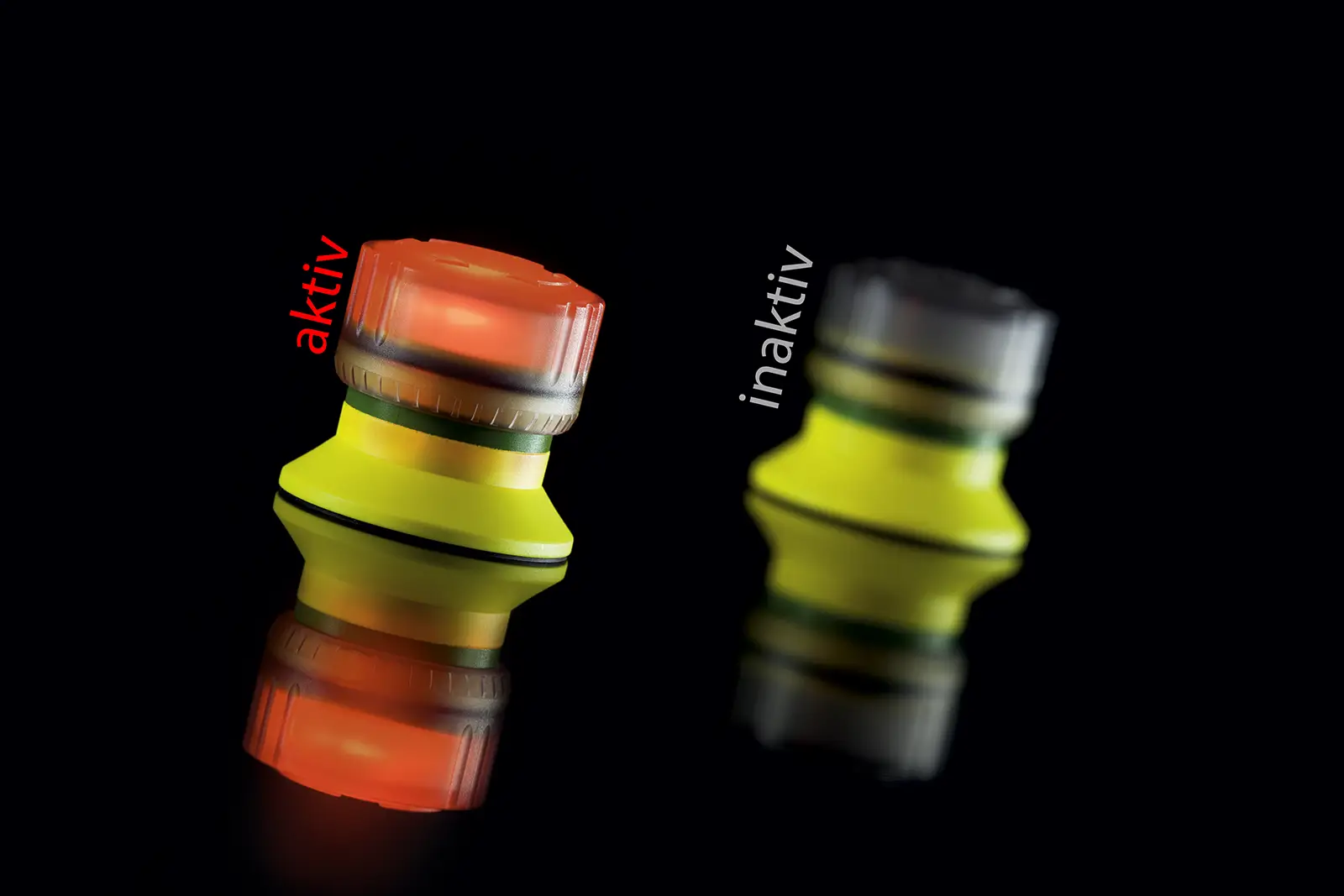

When mobile machines or machine parts are separated from active production, their emergency-stop also becomes inoperable. In the past, the inactive emergency-stop devices had to be covered to prevent an accidental operation. Since the revised norm EN ISO 13850:2015 became valid, another solution is possible: The usage of mushroom heads with red illumination which indicates an active emergency-stop. Inactive emergency-stops in contrast stay grey and are not recognised as an emergency-stop anymore.

In this article, you will learn which legal norms apply, which benefits active/inactive emergency-stops have and in which application areas they are being used.

Application of legal foundations and norms of the emergency-stop with illuminated mushroom head

In order to avoid the mixing up of active and inactive emergency-stops it was necessary for a long time to lock away or cover the inactive emergency-stop device to make it unrecognisable as soon as the corresponding operating panel or plant part was no longer connected to the overall system.

Since the EN ISO 13850:2015 came into effect emergency-stops can also indicate the actual operating status by a corresponding red illumination of the mushroom head. For a better recognisability of inactive emergency-stop devices, we have developed emergency-stops which signal the active and inactive status by using their illumination.

- Active (illuminated): device is ready for use

- Inactive (not illuminated): device is deactivated or without function

Benefits of illuminated emergency-stops

- Visible safety: operating status is immediately visible

- No cover necessary: the status is indicated clearly by the illumination, covering-up of the inactive emergency-stop is not necessary

- Increased diagnosis possibility: integrated electronics monitors the illumination

- Energy efficiency: inactive modules can be switched off

- Easy installation and mounting: standardised connections (e.g. M12)

Technical functional principle of the illuminated emergency-stops

Active/inactive emergency-stops are based on an electrical activation mechanism whose illumination is controlled via an integrated LED unit.

The control is done via a diagnostic unit which monitors the condition of the illumination signal. If the LED fails or a control is faulty, an emergency-stop signal is automatically triggered to guarantee the saftey of the plant.

The communication can be conducted via the M12 plug-in connector which enables an easy integration into existing systems.

Features

- Positive opening contacts ensure a reliable switch-off

- Degree of protection up to IP69K, depending on model and design

- LED illumination inside the mushroom head for status indication (red = active)

- Diagnostic unit monitors illumination intensity and function

Application areas and usage

- Modular production lines and interlinked plants

- Control panels in production and logistics

- Machine and plant engineering

- Hygienic areas in the food and pharmaceutical industry

- Automobile, ship and crane construction

Why illuminated emergency-stops are future-oriented

Modern production plants require intuitive safety concepts during their operation. The combination of a mechanical emergency-stop function and an optical status indication minimises reaction times in case of emergency and reduces faulty operations – an important factor for Industry 4.0 and interlinked machine parks.

Illuminated emergency-stops from GEORG SCHLEGEL

Georg Schlegel GmbH & Co. KG offers various types of illuminated emergency-stops:

- SIL_QRBDUVOOM125 - with diagnostic unit to monitor illumination: SIL enclosure, connection type M12 (built-in connector, 5-pole, A coded, AIDA), degree of protection in the front IP65, panel cut-out 22.3 mm, positive opening in accordance with EN 60947-5-1

- FRVKDOO_R0 - emergency-stop with status indication: Active (illuminated)/inactive(non-illuminated), emergency-stop from the Shortron series with small mounting depth, 2 NC, degree of protection in the front IP65/IP67, panel cut-out 22.3 mm, yellow housing, connection via Faston clamps, colour of mushroom head: red/grey, positive opening in accordance with EN 60947-5-1

- YVDOO_R0 - emergency-stop with status indication active/inactive from the mYnitron series, compact design and small mounting depth, yellow housing, 2 NC, degree of protection in the front IP65 / IP67, round shape, colour of mushroom head: red/grey, connection via Faston clamps, positive opening in accordance with EN 60947-5-1

- Individual solutions on request – such as complete systems with control panel.

Depending on the model, the active/inactive emergency-stops are available with anti-lock collar, key release, twist to release or pull to release as well as enhanced diagnostic functions.

Further information about general data, technical documentation or assembly on request.