Cost-effective, installer friendly and flexible control devices: Schlegel launches a modular operating concept for bus systems

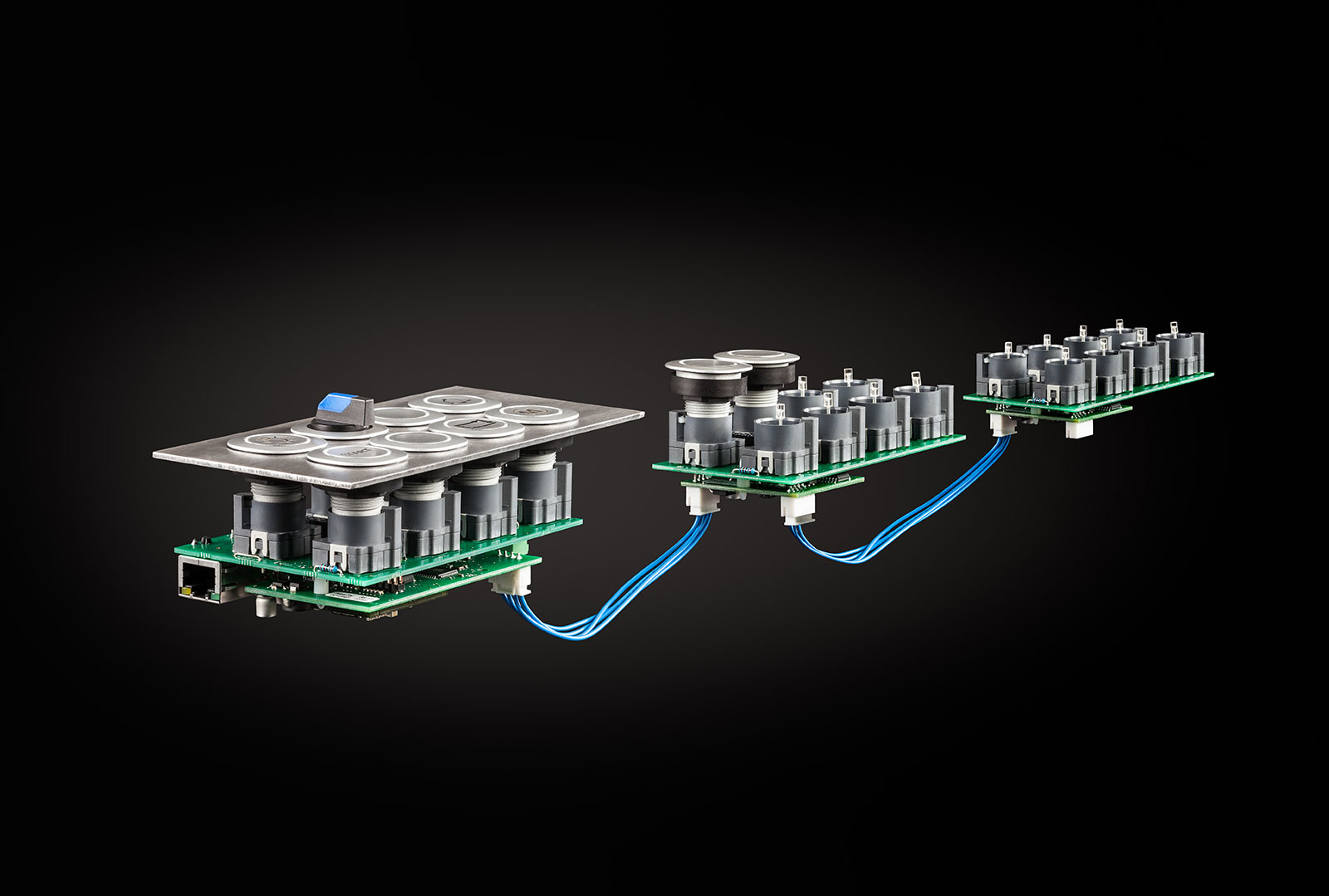

The great advantage of the modular operating concept is the connection of several expansion modules via a basic module and the associated saving of costs. Only the basic module includes the bus-specific bus connection and the bus node which communicates with the corresponding bus system. Thus, the basic module is the most complex module of the total package. The expansion modules are connected via a cable connection to the basic module, which then communicates with all connected command points. The usual additional cabling of the command points is no longer necessary, thus, saving installation time and reducing wiring outlay and space requirement. Moreover, customers who opt for the modular control concept, enjoy high long-term flexibility. If their requirements change, for example if more actuators are required, the modular operating concept can be expanded at any time until the maximum number of expansion modules is reached. Also, switching to a different bus system can be implemented quickly. For this purpose, only the basic module needs to be replaced by one that is compatible with the new bus system, no further installation work must be done. Thanks to its modular and standardised design, the operating concept is suitable for all applications and allows cost-optimised solutions even at quantities of only 10 to 20 units – a fact that is of particular interest for the special machinery construction with small lot sizes.

„Our basic idea was to develop an operating concept that makes us flexible enough to provide low-cost up to high-end solutions”, says sales manager Wolfgang Zoll, and comments further ”As far as I know, there is no equivalent concept in the market.”For the implementation Schlegel relies on standardised modules in fixed grid spacings. Each module is construed with eight inputs for snap-action contact blocks and eight outputs for integrated LEDs or pluggable LEDs as an option. Depending on the application, a total of 64 I/Os (for control panel construction) or 128 I/Os (for plant engineering and construction) can be implemented. Though the modular operating concept is highly standardised, it allows adaptation to individual customer requirements. If the special design plans of the customer cannot be implemented with the standardised modules, Schlegel resorts to sub-modules out of the modular operating concept while adapting the carrier card to the command points (PCB with individual contact blocks) according to the requested design. Combinations of standardised and customised modules are even more cost-effective than entirely customised solutions. „With the modular operating concept, we have succeeded in developing a future-proof and dynamic system to integrate contemporary design and state-of-the-art technology in modern machine concepts and panel layouts“, says Mr. Zoll.

Different application in the industry sectors control panel construction and plant engineering & constructionWe distinguish in this modular operating concept two basic applications: Control panel construction in which all command points are summarised on one area, and plant engineering & construction with several command points, which are distributed over the system.For the control panel construction, the command points are arranged on one control unit, on which we can set up max. 64 command points with 64 indicator lamps. This requires eight modules (basic module + seven expansion modules), which are connected through with a ribbon cable. On this arrangement, the individual modules are mounted in a max. distance of 250mm to each other.In the plant engineering & construction, the complete plant is considered, which usually has one main control panel and several secondary control panels. The main control panel is equipped with the basic module and possibly with several expansion modules. Here is also located the bus node with the typical bus connection. Existing secondary control panels can now be equipped with additional expansion modules. In this application a max. of 128 command points with 128 indicator lamps (basic module + 15 expansion modules) can be operated. A max. cable length of 5m is possible between the command points, the total length within the plant can be up to 30m.Schlegel offers the standardised modules in fixed grid spacings of 25 x 25 mm / 27 x 27 mm /30 x 30 mm. The individual modules can be attached in the same spacing. Thanks to a simple plug-in principle, no additional spacers must be installed in the front panel for fastening the modules. The basic module is supplied with a supply voltage of +24V/DC and with the bus signal. The modular operating concept is available for the following bus systems: AS-Interface, CANopen, Profibus, EtherCAT, Profinet I/O and Ethernet IP.

About Schlegel GmbH & Co.KG

Schlegel stands for innovation, quality and design. Founded in 1945, Schlegel is today a globally operating company with headquarters in Germany, sales offices in Austria and Singapour and exports to more than 80 countries on all five continents. The core competences: Development and production of control units, pilot lights and terminal blocks. The product portfolio further includes bus systems, enclosures, limit switches, control panels and function modules. When developing new products, Schlegel sets high standards on the design. More than 90 national and international design awards confirm the company’s high level of design expertise. Among these prizes, the iF Design Award, the Red Dot Award and the German Design Award.